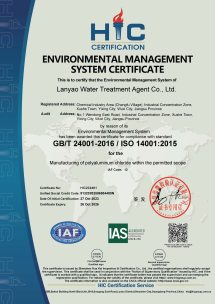

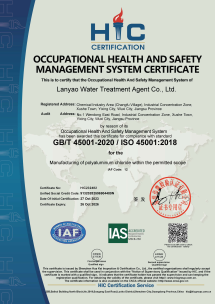

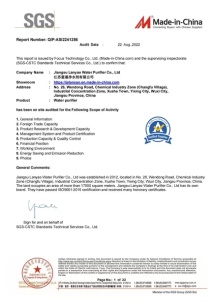

LANYAO WATER TREATMENT CO, LTD, founded in the early 1990s, is currently located in the chemical area of Yixing Industrial Zone, Jiangsu Province, with 20000 square metersfactory area. It is a professional enterprise that integrates research, production, sales, and technical after-sales servic e of water collection treatment agents. Lanyao has a registered capital of 30 million RMB and an annual profit and tax of over 28 million RMB. The company currently has more than 80 employees and has a complete set of production management processes and quality supervision systems. It is supported by advanced testing equipment and mature process systems, which have enabled the company to win praise and trust from numerous domestic and foreign users with high-quality products and services. Our company's organizational structure consists of five departments and one office: Marketing Department, Technology Research and Development Department, Business Management Department, Engineering Business Department, Financial Settlement Department, and Comprehensive Office. The Engineering Business Department has Nantong Branch, Suzhou Branch, Jiangxi Branch, and Hong Kong Branch. Our company has passed ISO9001 quality system certification , ISO14001 environmental system certification, occupational health and safety management system certification, CE, ROHS, SGS and other international certifications since 2012. The business of industrial water medicament and drinking water medicament is widespread, covering Jiangsu, Zhejiang, Anhui, Shanghai, Jiangxi, Fujian, Northeast, Xizang and other places in China, and Vietnam, Thailand, Malaysia, Indonesia, Russia, Europe and other countries overseas.